Your Watch, Your Story: The ALB Tailor-Made Experience

Share

At ALB, custom watchmaking is much more than just a watch manufacturing process.

It is a unique and collaborative experience, where we support our clients at each stage of creation to bring to life a piece that resembles them.

Our approach is based on three fundamental values: work, time and transmission. These values are embodied in the customization, creativity and exclusivity of the watches that we co-create with our customers.

ALB's three core values

1. Work: co-creation with the client

Creating a custom watch requires careful attention to every detail. Our clients are actively involved in the design process. We offer them the opportunity to choose the aesthetic and technical directions of their project.

Simon-Pierre working on a piece with his ankle

2. Time: take the time for precision

Time is a crucial dimension in the creation of a custom watch. Each step, from design to manufacturing, requires thought and patience. The production of custom components can last several weeks or even months, depending on the complexity of the project.

3. Transmission: a watchmaking heritage

Custom creation is also an act of transmission. We share our know-how with our customers, so that they can convey their values and create a watch that can be passed down from generation to generation.

The three levels of customization offered by ALB

To meet the specific expectations of each client, we offer three levels of customization, linked to the pillars of the ALB brand: creativity, imagination, and exclusivity.

Level I | Creativity: assembling components

This first level of customization allows customers to choose watch components from our catalog. This includes the choice of Swiss movement, case, hands, and finishes.

Example of an ALB watch assembled for a customer from parts available on the market

Level II | Imaginary: designing the dial

At this level, we work with the client to design a unique dial, integrating symbolic elements defined by the client, such as patterns, decoration techniques or personal aesthetic inspirations.

Work on the dial of the ALB Etretat watch

Level III | Exclusive: a 100% original creation

This level of exclusivity offers the possibility of creating a completely original design for the case, dial, hands and decorations. The customer is thus at the heart of the design of a totally unique watch, incorporating precious materials and cutting-edge artisanal techniques.

Example of an achievement: The ALB Streamliner watch developed on the basis of a Delahaye flywheel

Unique materials and techniques

We integrate precious materials such as gold, silver, platinum, and precious stones into our creations, using jewelry and glyptic techniques. We are also developing traditional watchmaking techniques such as grand feu enameling and pad printing.

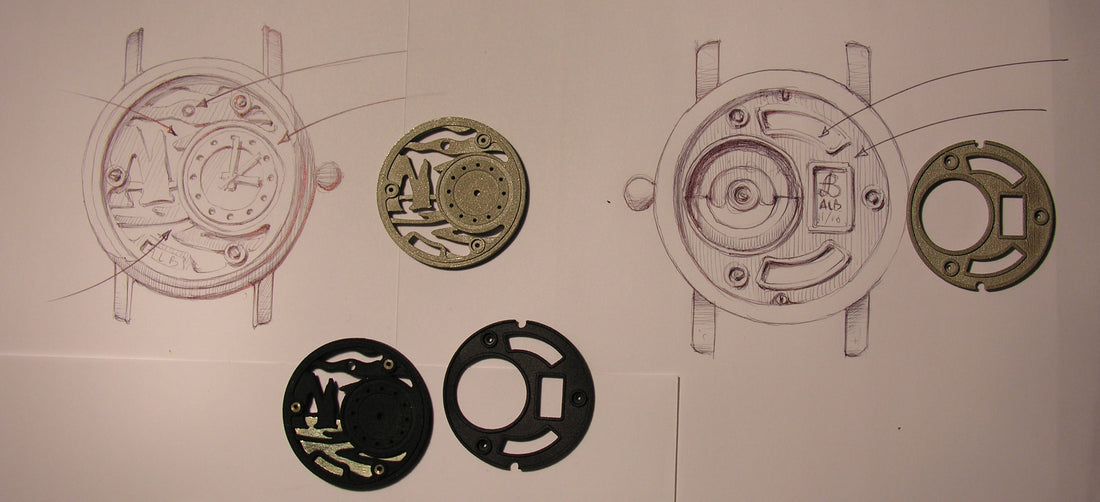

For the manufacture of custom components, we use 3D prototyping, lost wax casting and conventional machining, thus guaranteeing the precision and exclusivity of each piece.

A 3D printed ALB watch case prepared for casting

The tailor-made creation journey with ALB

The creation of a custom watch at ALB always begins with a design meeting with Simon-Pierre and Vincent. During this meeting, the client's expectations are discussed in depth to define the broad outlines of the project. This collaborative process allows us to create a watch that perfectly embodies the client's universe, imagination and values.

Conclusion: A unique experience for each customer

ALB reinvents custom watchmaking by combining traditional craftsmanship with modern techniques such as 3D prototyping.

Each watch we co-create with our customers is a reflection of their imagination, their creativity, and their story.

Want to create a custom watch with ALB?

Do not hesitate to contact us by email or telephone.